Cylinder Surface Restoration in a Dryer Section

Grinding of 16 dryer rolls in a paper machine´s dryer section during a maintenance shutdown

Problem:

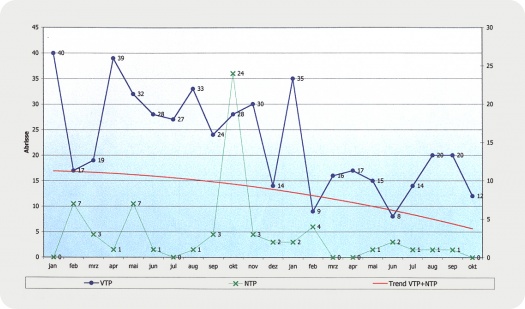

Variations in cylinder diameters and partly poor surface conditions led to frequent paper tears and reduced product qualities.

Works performed:

- Identifying and evaluating the actual condition of the drying section by measuring the cylinder diameter.

- Detailed definition of the grinding work to do on the various cylinders.

- Determining the optimal group/set diameters.

Special features:

- The grinding of the drying cylinders had to be executed within the time frame for the installation of a Flow Speed of Voith Sulzer.

- That means, 16 dryer rolls had to be ground within 8 days in situ.

- The grinding of the cylinders had to be coordinated with the simultaneously performed maintenance activities on the machine.

Result:

- The schedule for the grinding has been observed.

- The demanded paper quality has been achieved, the number of paper tears could be reduced significantly.