Profile grinding – a tangential grinding procedure

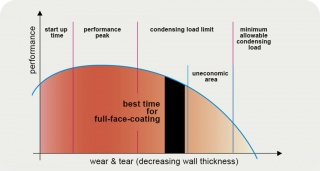

Besides polish grinding, predominantly used to optimize surface quality and roughness, profile/form grinding can be considered as one of the most important Yankee reconditioning procedures.

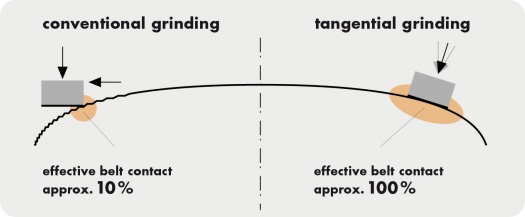

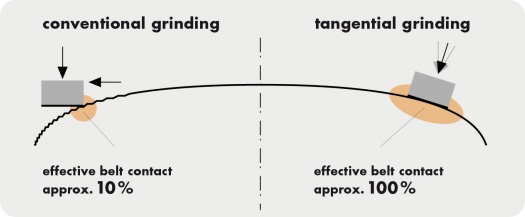

The tangential grinding procedure guarantees highest precision with a high removal rate combined with the lowest possible material removal and thus wall thickness reduction.

This modern grinding technique preserves material and no longer requires pre-tooling.

The compact grinding equipment can easily be installed on either the doctor side or the press roll side. The grinding equipment can be mounted directly on the press arms, which makes this an ideal installation option. On the doctor side the machine guide can be mounted to the doctor brackets. ►►

Problem:

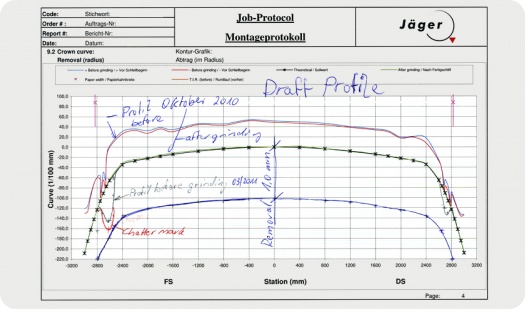

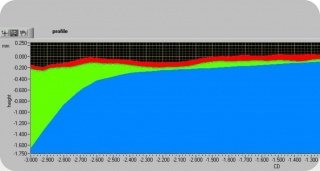

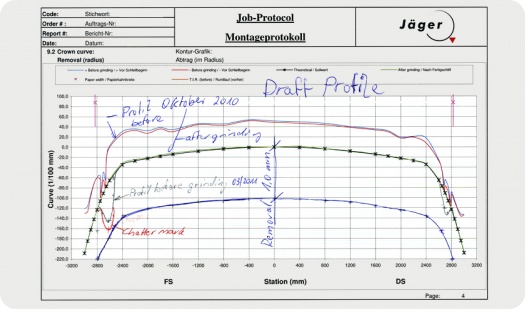

Modern Yankees are generally crowned, to compensate for cylinder deformation from operating temperature, pressure and defined press loads. Grinding a Yankee the theoretical crown needs to be restored at calculated grind pressure.

Following multiple Yankee grinds and consequential a shell thickness reduction, the manufacturer's reference value for crowning will no longer be the ideal value for the cylinder in operation. In such case JAEGER offers recalculation of the theoretical crowning prior to the grind. The same applies to operation under other than the manufacturer's set of operating values. Correcting the cylinder geometry with a profile grind based on incorrect set values is a worst case scenario ...

Solution:

With tangential grinding the angle of the grinding head is adjusted during the grind. Not only to keep the material removal to a minimum in order to preserve cylinder shell thickness, but also to achieve a flat and smooth surface, especially at the generally steeply crowned edges.

Advantages:

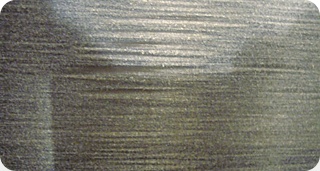

The high and smooth surface quality as well as the ideal crowning resulting from tangential profile grinding will improve product quality considerably, prolong the life of the doctor blade and reduce coating chemical usage.

Our high performance grinding equipment reduces grinding time and consequently minimizes the required machine down-time.